Reliable bypassing of stenoses in the area of the digestive or respiratory tract places high expectations on a stent. With its extensive range of stents, MICRO-TECH Endoscopy, as one of the leading international manufactures, meets these requirements and offers a suitable solution for many challenges. Rely on the utmost in quality and optimum positional stability.

NITINOL STENTS

NITINOL STENTS FOR GASTROENTEROLOGY

SELF-EXPANDING STENTS

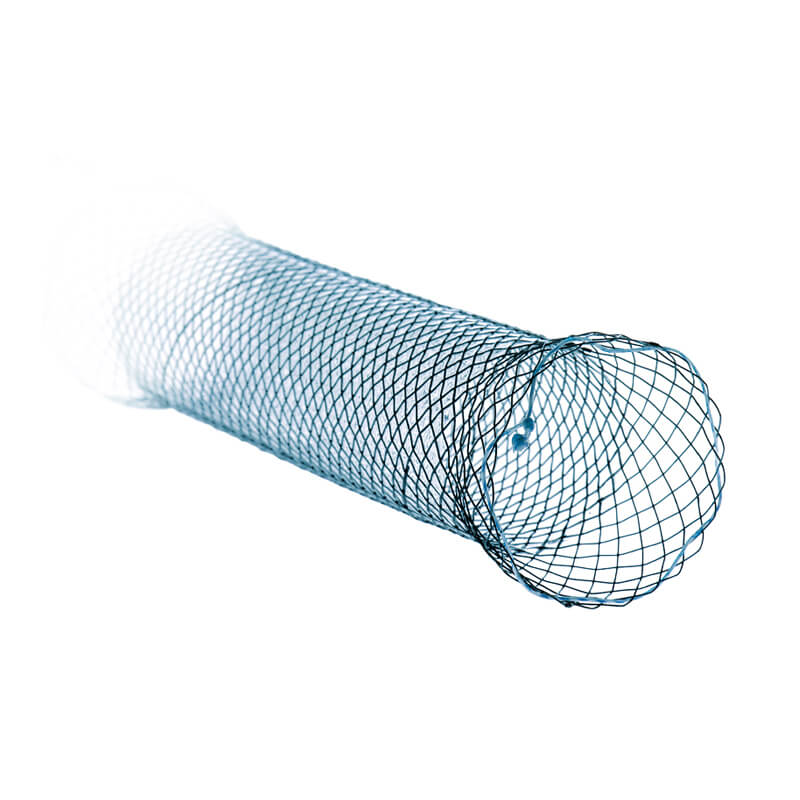

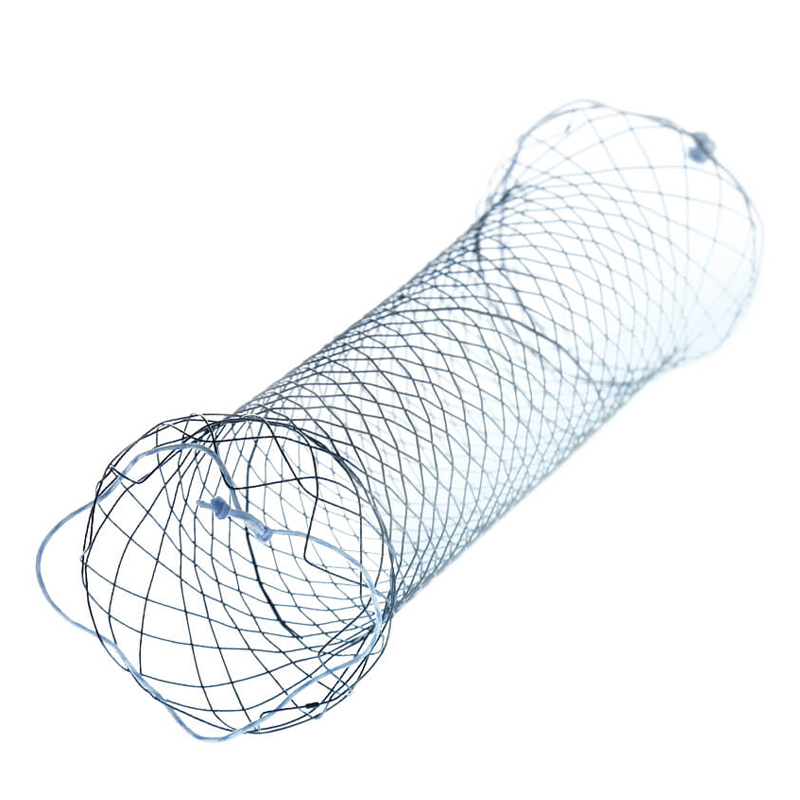

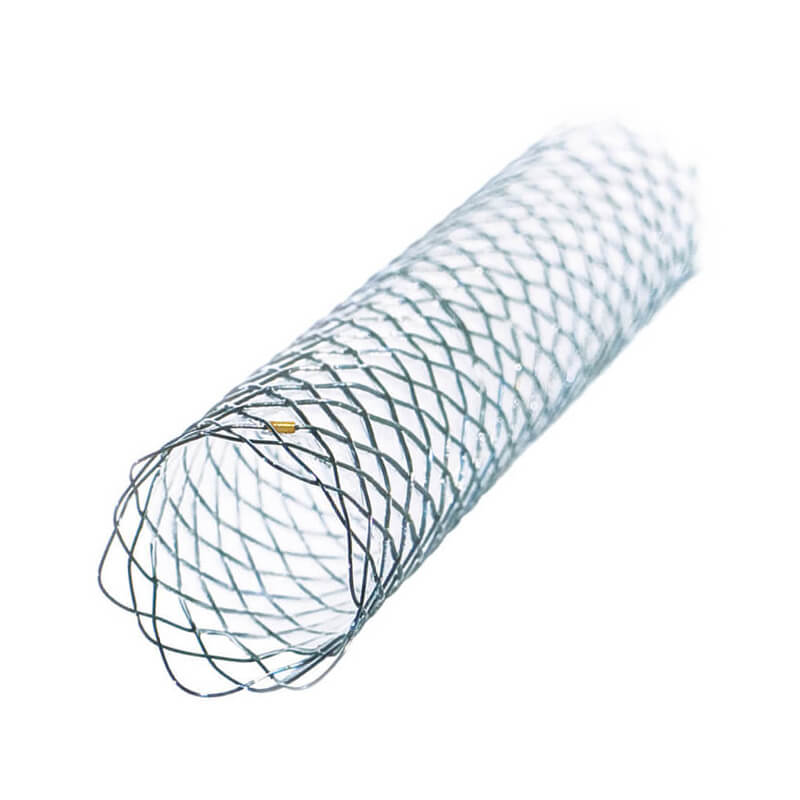

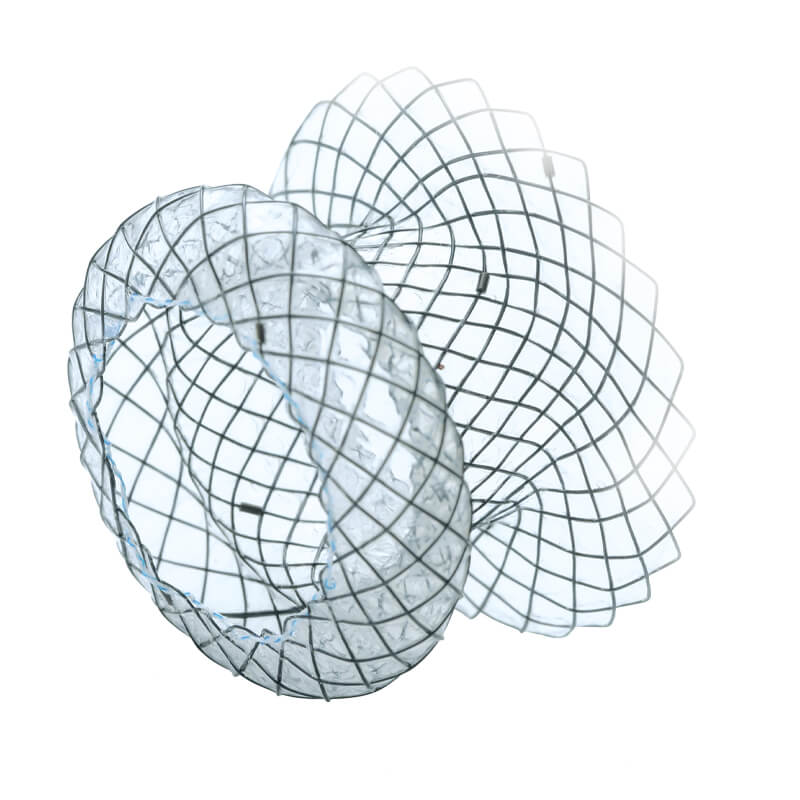

Every stent from the MICRO-TECH Endoscopy range is manufactured using high quality Nitinol wire. The “thermal memory effect” of Nitinol causes the released stent to unfold into its predetermined dimensions at body temperature. It therefore adapts to the anatomy and achieves the desired dilation of the stenosis in an optimum manner.

SIMPLE TO RELEASE

In order to make release of the stent as easy as possible, the stents are preloaded on an introducer. The system can be manipulated intuitively and effortlessly. With some stents you even have the opportunity to correct the positioning of the stent during implantation.

MANUFACTURED FROM ONE WIRE

MICRO-TECH Endoscopy Nitinol stents are – with the exception of the segmented stent – braided from one single wire. This significantly minimises the risk of asten t fracture at connecting loops.

PRECISE POSITIONING VIA X-RAY MARKINGS

In order to allow you to position the stent precisely, additional X-ray markings are provided on the introducer and the stent, which can be easily distinguished under X-ray fluoroscopy. The good radiopacity of the stents further reinforces this effect.

X-ray markings